Client

Our Client is a European manufacturer of timber and wood products, exporting its goods to businesses throughout Europe and Asia. The company has manufactures in the UK, France, Lithuania, and other countries.

Challenge

The Client managed their daily manufacturing and financial workflows without a unified management system, using different XLS/PDF files, emails, and papers. The process was full of manual work.

Key departments were blocked from access to new sales orders

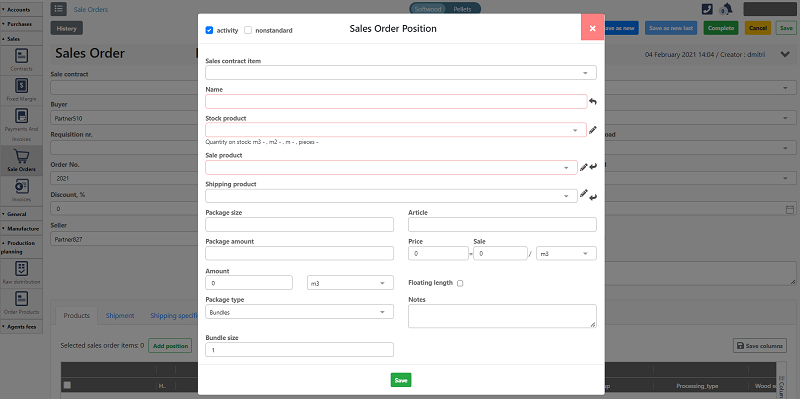

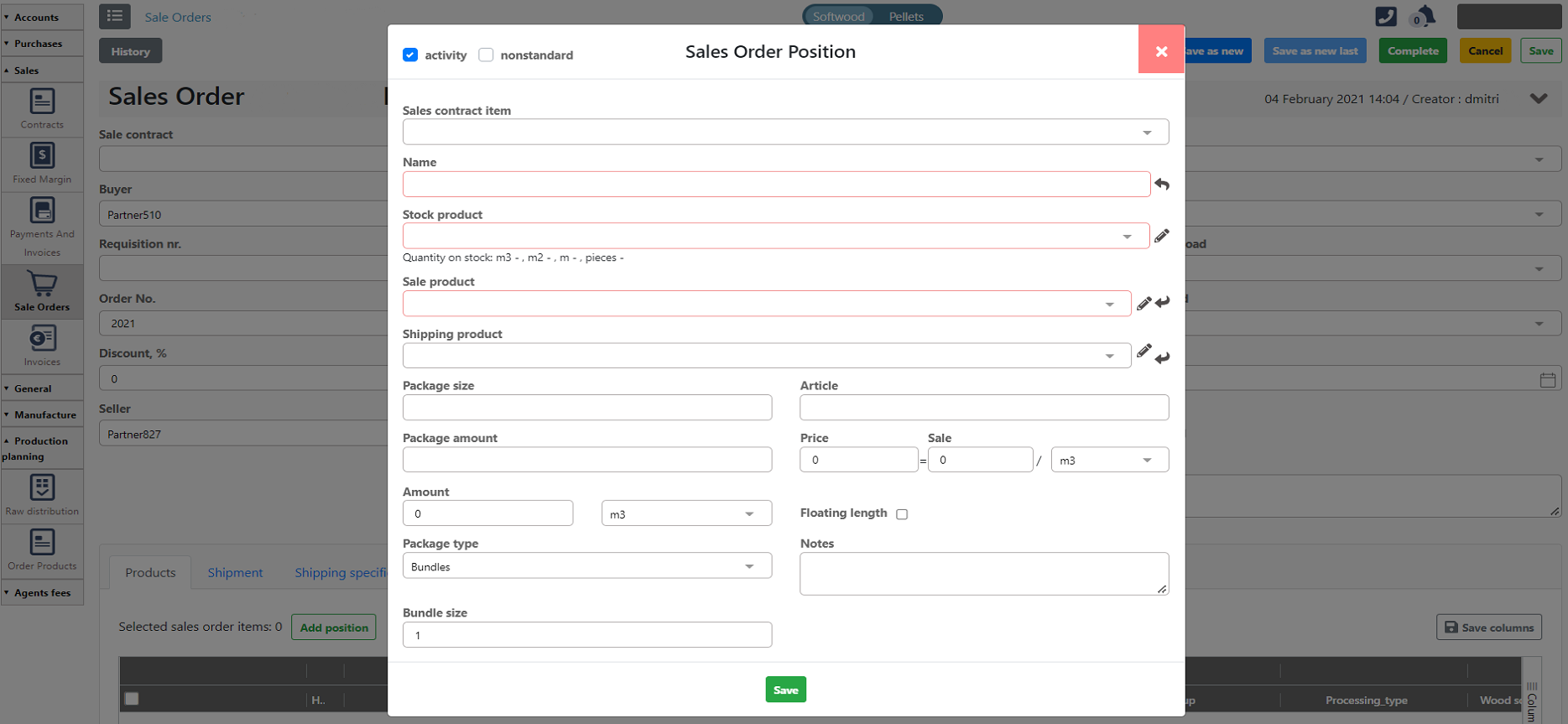

A sales manager created a new order in an XLS file. The order was stored locally, so the procurement, manufacturing, and accountant departments were forced to request it every time. They depended on sales managers even on such routine tasks.

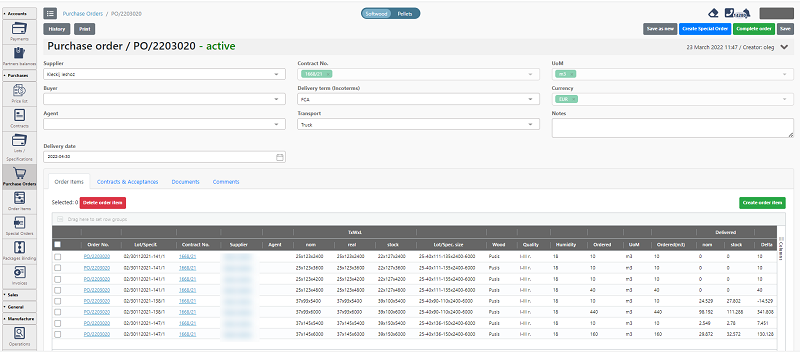

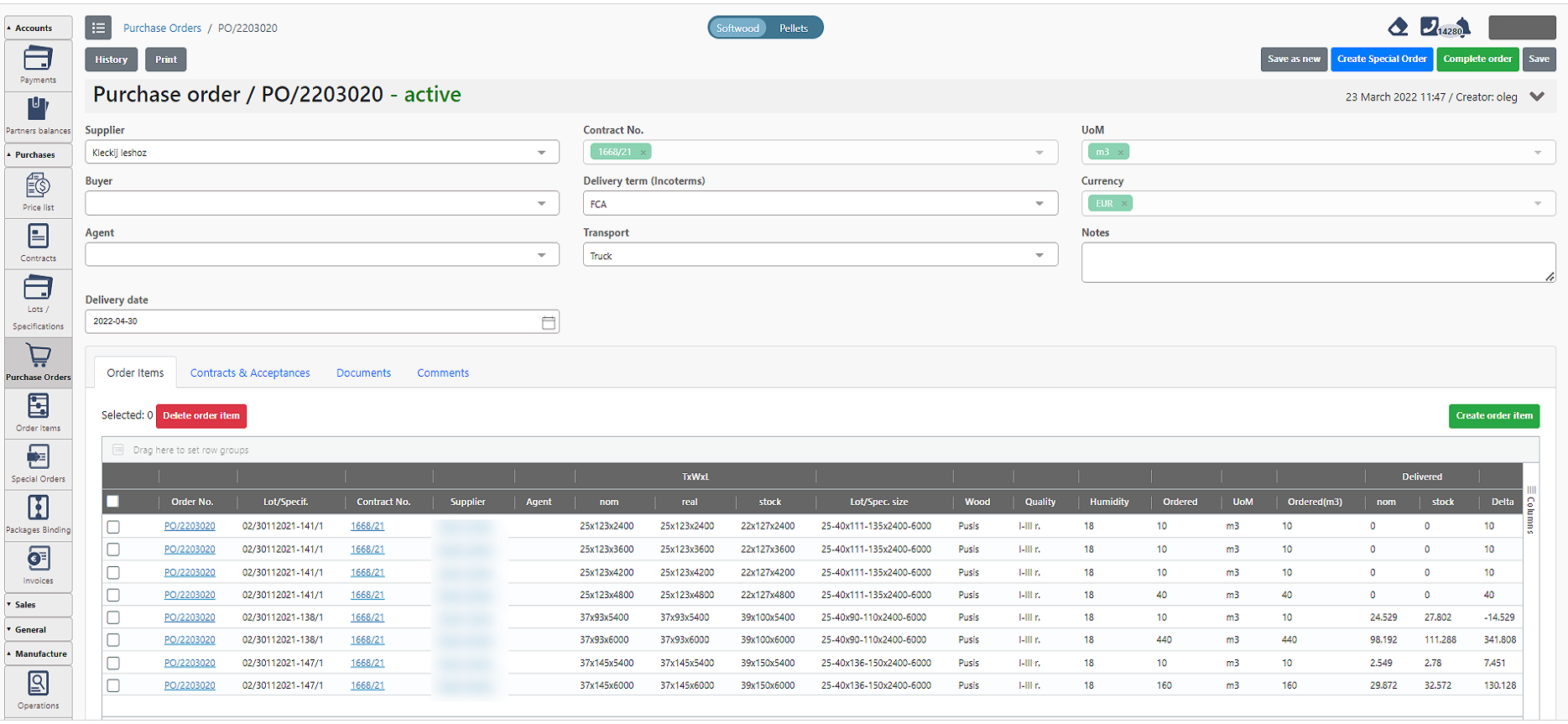

- Procurement managers weren't able to fulfill the stock timely. The procurement manager estimated available raw materials to decide about stock fulfillment, without knowing the number of new orders.

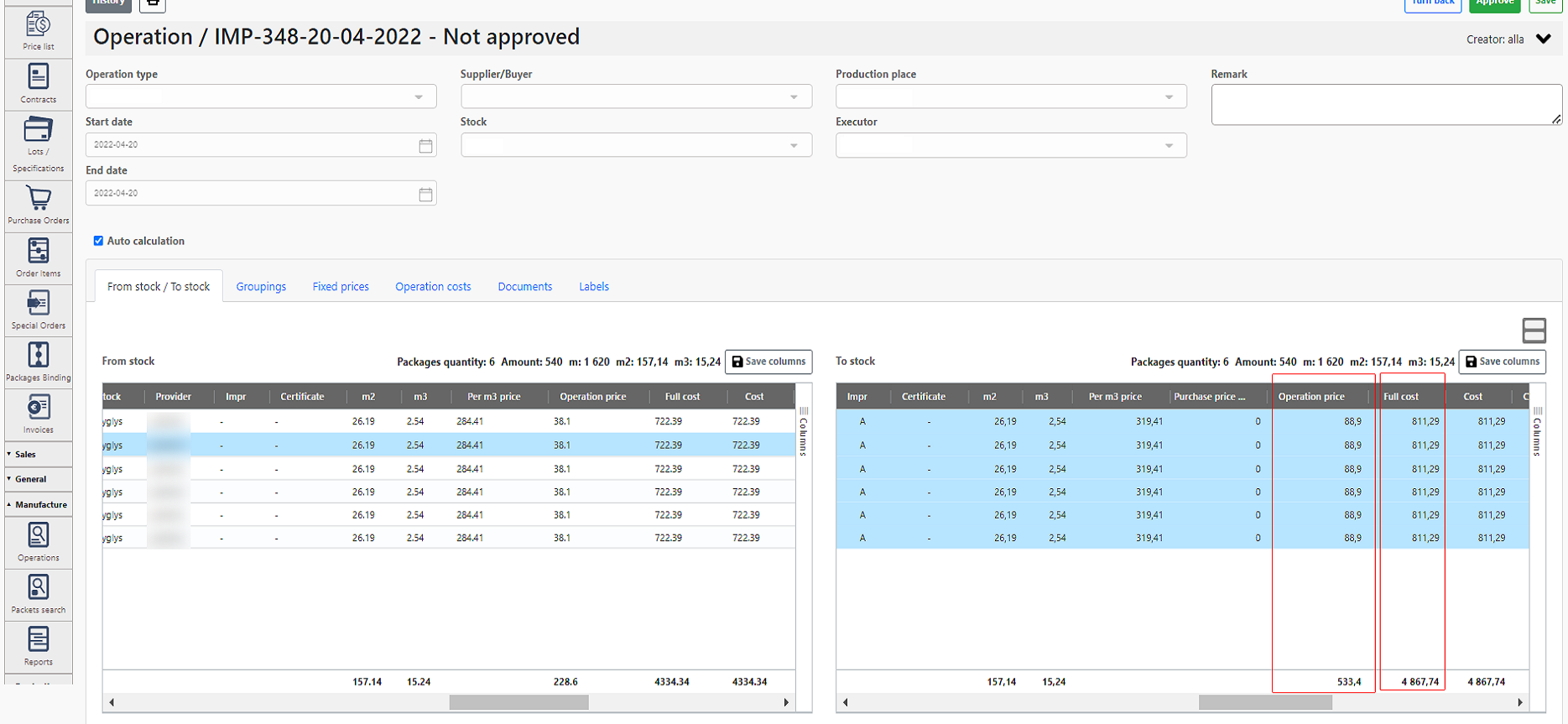

- Manufacturing staff were unhappy to manually verify defected products and calculate manufacturing costs. The head of production expected an email from the sales manager with order details to start manufacturing. During the process, they had to manually track the amount of defective goods. At the end of production, they were obliged to manually calculate manufacturing costs.

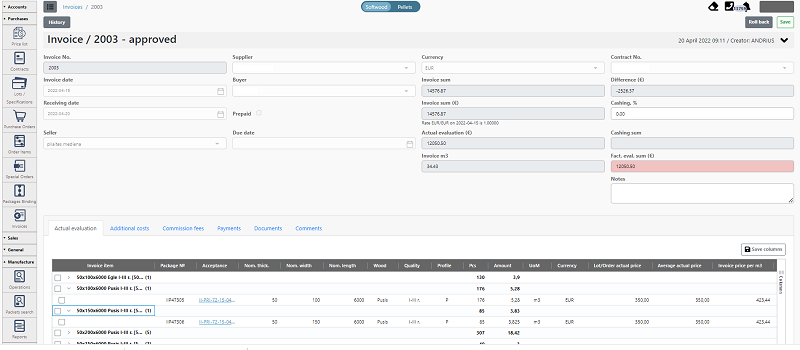

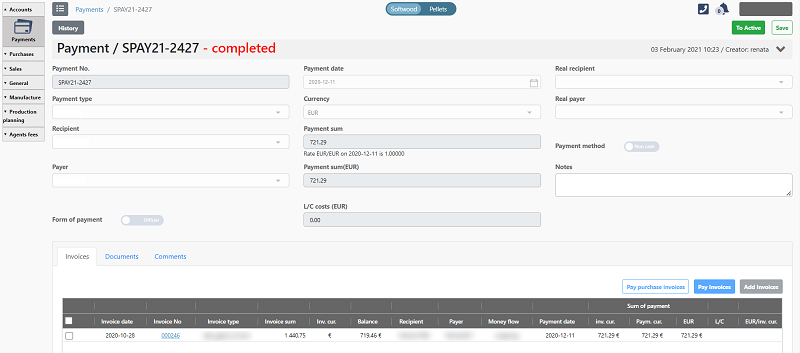

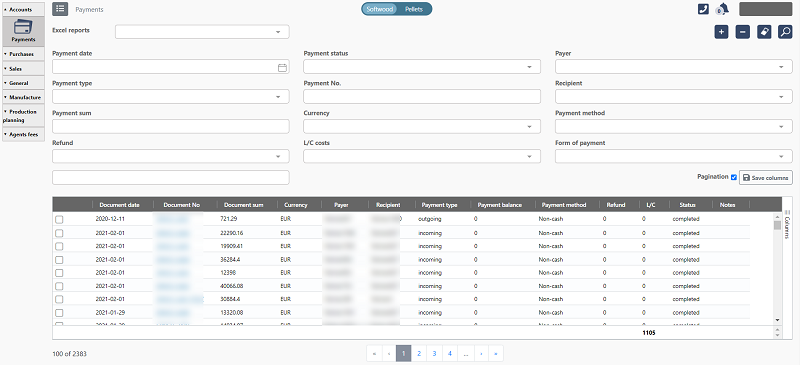

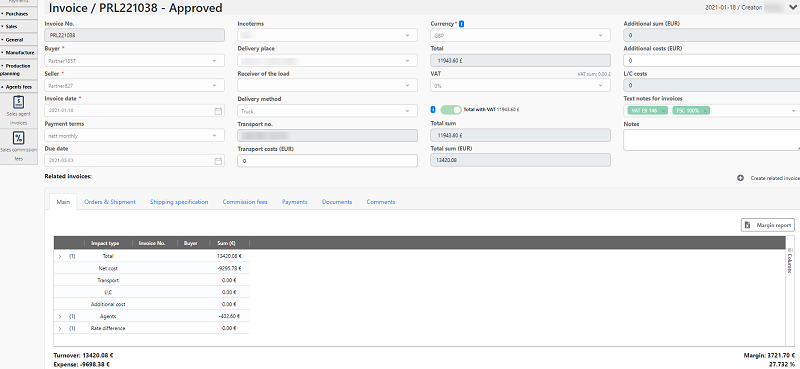

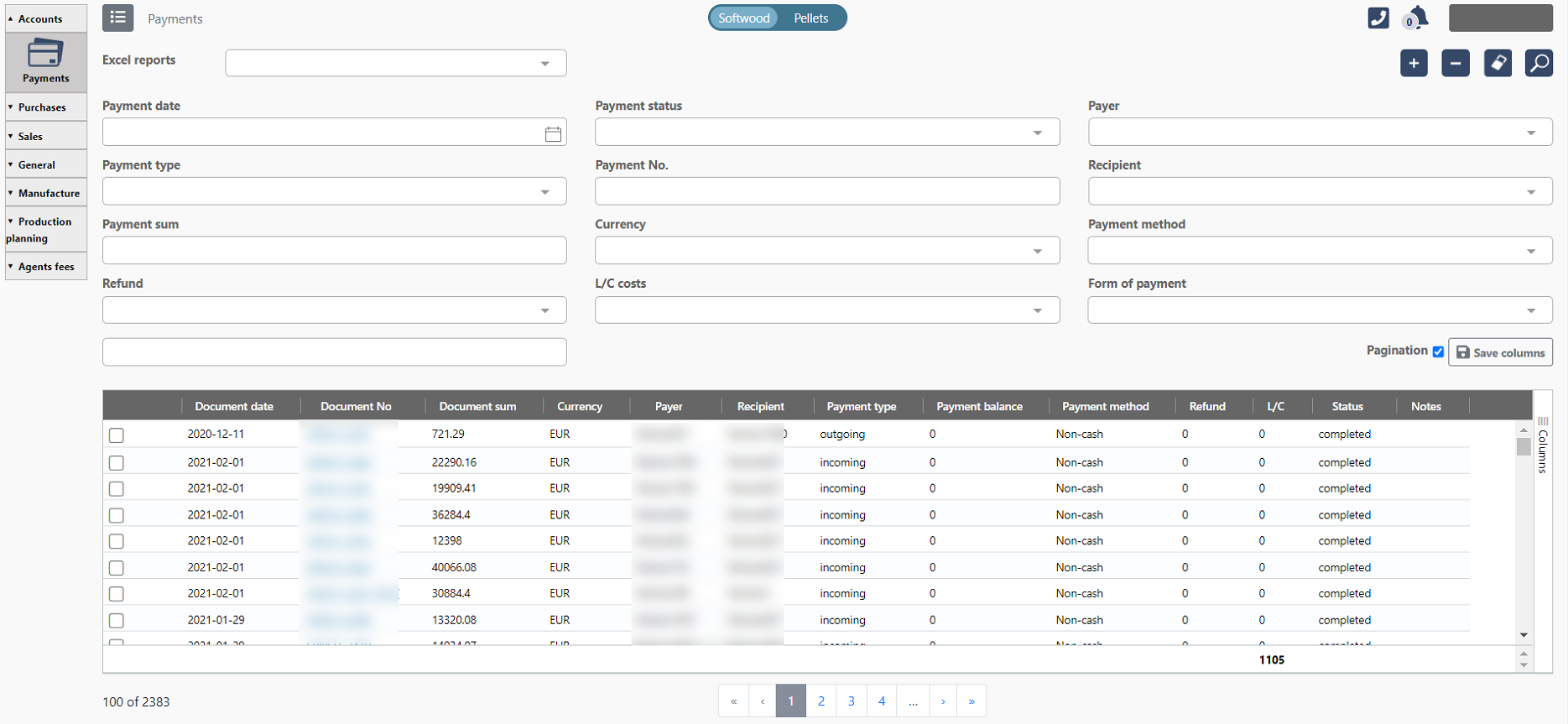

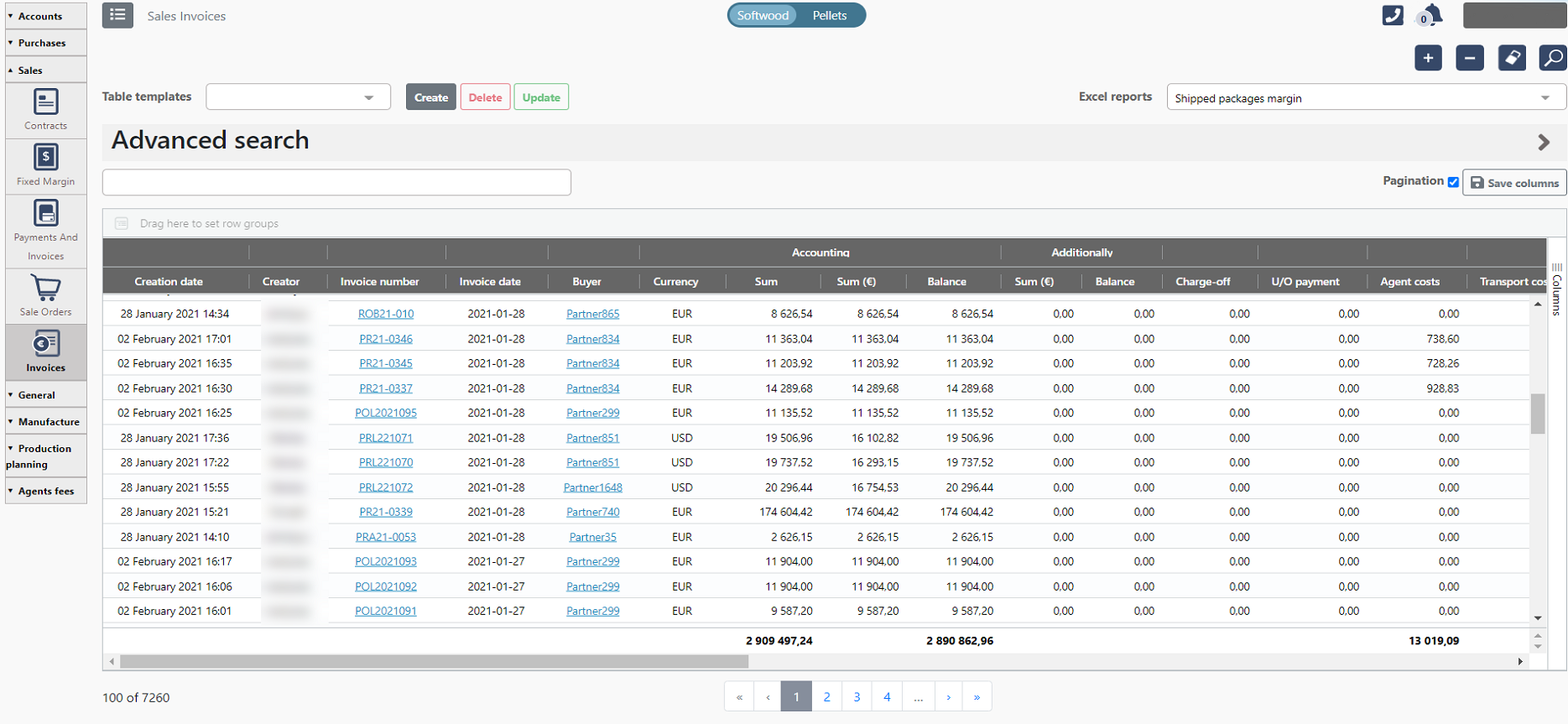

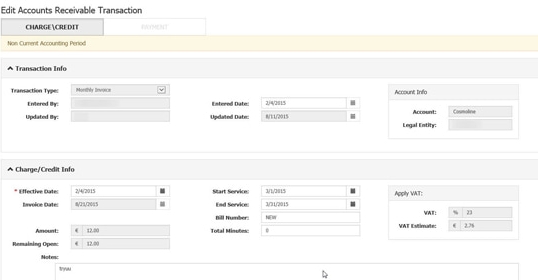

- Accountants had no single database, where all bookkeeping information was synchronized. The accountant collected emails from various departments and manually entered the data into the accounting software to calculate payments.

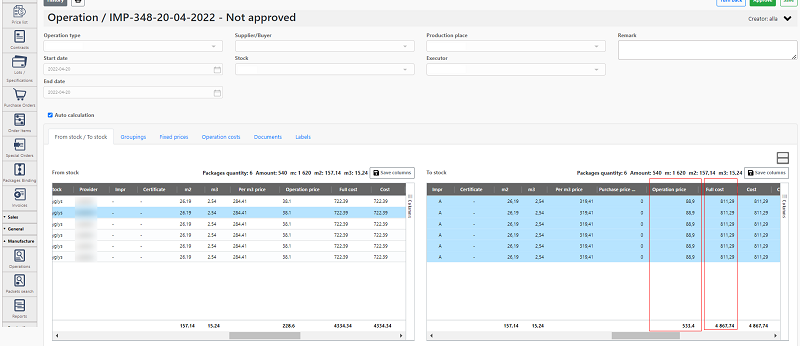

Warehouse employees had to manually get and pass the info to the procurement managers

The procurement manager created an operation and sent a request to a warehouse employee. The employee handled the pallet and confirmed task fulfillment before returning to their workplace.

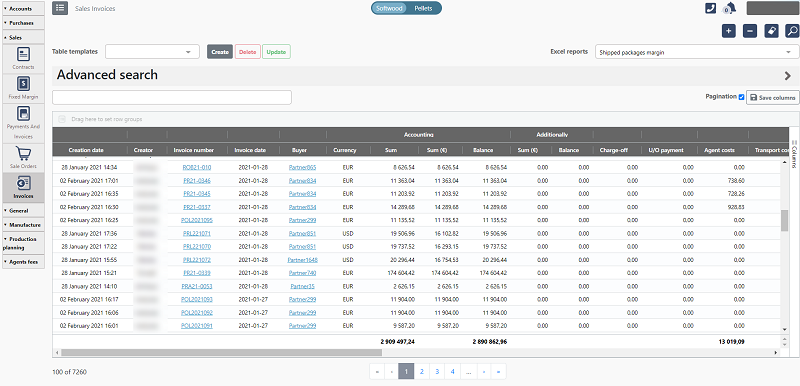

Sales managers had no tools to track order readiness and delivery status

The data about produced and shipped products was manually entered by sales managers. In the case of large orders, that are often sent in several batches, and it was complicated to monitor which part of the order was shipped and which was still in production.

Business leaders didn't have real-time data about company operations in a single place

Business stakeholders requested employees to make regular reports manually. Without a complete cost-effectiveness picture, they couldn't make timely and data-driven decisions.

A matter of urgency and lack of in-house development expertise

Opening new manufactures in Europe made it crucial to reduce human errors, improve data accuracy, and access company data in real time.

For that, our Client needed a customized ERP solution to automate the manufacturing and financial workflows and create full visibility of key business processes.

Since they lacked in-house developers, they chose Belitsoft as their technology partner. We quickly provided them with a full skilled team specializing in ERP development.

Solution

Process

Results

Rolandas Zacharevičius

Founder of the Company

Related cases

Recommended posts

Our Clients' Feedback

.jpg)

.jpg)

.jpg)

.png)

Belitsoft has been the driving force behind several of our software development projects within the last few years. This company demonstrates high professionalism in their work approach. They have continuously proved to be ready to go the extra mile. We are very happy with Belitsoft, and in a position to strongly recommend them for software development and support as a most reliable and fully transparent partner focused on long term business relationships.

Global Head of Commercial Development L&D at Technicolor